New Civil Engineering Building instrumented with six sensor packages

Funded as part of a £138M UK Government investment in infrastructure and cities research (part of the UKCRIC network), the new Civil Engineering building is instrumented with six sensor packages, from the roof to the foundations. Academic and research staff from the University's Civil Engineering Division are developing the technologies to display, store, interpret, and visualise these data streams. This information will be used to understand the performance of the new research facility and assess this performance against the predictions made during design. By examining any differences, they aim to understand performance, and help improve future design.

Introduction

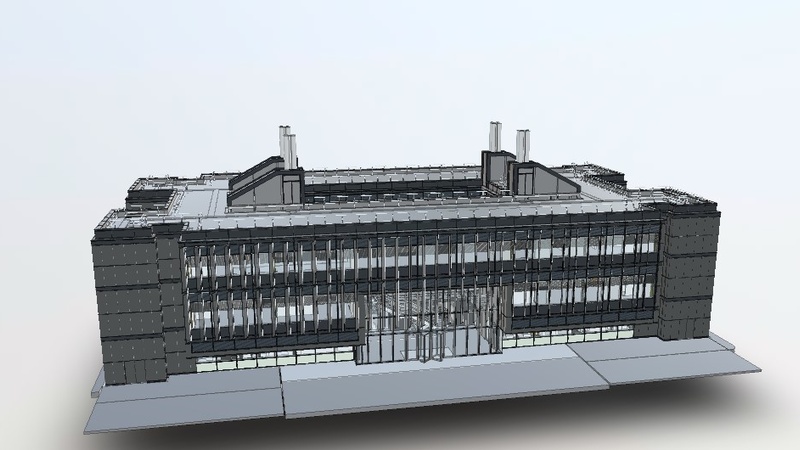

Funded as part of a £138M UK Government investment in infrastructure and cities research (part of the UKCRIC network, see http://www.ukcric.com/) the new Civil Engineering Building is currently under construction at our site in West Cambridge. The building was designed by Grimshaw architects, and will house the majority of the civil engineering team, along with the National Research Facility for Infrastructure Sensing (NRFIS). The building is three storeys in height and occupies a plan area of 32.4 x 57.6 m.

The building is instrumented with six sensor packages, from the roof to the foundations. The sensors are an integral part of research being undertaken in Civil Engineering at Cambridge and link closely to the Centre for Smart Infrastructure and Construction (CSIC), also at the University of Cambridge. We are developing the technologies to display, store, interpret, and visualise these data streams. This information will be used to understand the performance of the new research facility and assess this performance against the predictions made during design. By examining any differences, we aim to understand performance, and help improve future design.

Figure 1: New civil engineering building

Context

The global construction industry is worth $10tr annually and creates and maintains the built environment that emits about half of the planet’s carbon emissions. Construction creates the vast majority of the infrastructure that is essential for trade and commerce. It underpins the productivity of most industries, and the healthiness of building occupants.

Despite this, we still know surprisingly little about the real performance of buildings, and their interaction with occupants. In order to understand such interconnections, efforts must be made to measure effects in a continuous manner. This has only recently become possible at scale, as exemplified in NRFIS and through the work of CSIC. This progress has not yet been matched by the same level of understanding of what to do with the sensor data. How can it be turned into something useful, beyond specific criteria in one building?

What is being instrumented?

As part of the funding for NRFIS, the building has been instrumented in six major areas:

Distributed temperature sensing in ground source heat pump (GSHP) boreholes

- Led by Professor Giulia Viggiani

- Temperature-sensing DFOS loops in 2 GSHP boreholes and 1 sacrificial borehole. Total of 980m of DFOS sensing cables.

- Embedded sensors in the basement raft and perimeter walls

- Led by Dr Mohammed Elshafie

- Strain- and temperature-sensing distributed fibre optic sensor (DFOS) system and a fibre Bragg grating (FBG) sensor system, to monitor long-term ground effects on the basement structure

- Two DFOS and two FBG loops installed in the raft (top and bottom of the raft), as well as four FBG loops in the retaining walls (one in each wall), to be monitored intermittently.

- Total of 120m DFOS sensing cables and 108 FBG sensors.

Embedded sensors in the strong floor slab

- Led by Dr John Orr

- Strain- and temperature-sensing DFOS system and FBG sensor system, to monitor the effects of experimental loading on the strong floor slab, as well as long-term relaxation of post-tensioning.

- 12 DFOS and 10 FBG loops (top and bottom of slab), to be monitored intermittently

- Total of 640m DFOS sensing cables and 319 FBG sensors.

Sensors on the frame structure

- Led by Dr James Talbot

- Strain-sensing FBG sensors to monitor the long-term performance of the structural frame of the building under occupancy loading.

- A single frame comprising of 12 columns and 9 beams instrumented with one sensor pair each (one sensor on each flange), to be monitored continuously

- A total of 42 sensors comprised of 66 FBGs.

Blue roof instrumentation

- Led by Dr Dongfang Liang

- Weather condition, soil moisture content, water level and temperature sensors

- To assess the effectiveness of the blue roof, as well as provide environmental parameters for the other sensing packages.

Building environment sensors

- Led by Dr Mauro Overend

- Suite of measurements including: Volatile organic compounds, humidity, air velocity and temperature, radiative temperature, lux levels, noise levels, energy use, CO2 levels, lights, windows, heating controls, façades: inner and outer surface temperature; inner, outer and cavity air temperatures; external, internal and cavity humidity level (when an air cavity is present); solar radiation and lux levels close to the façade; and outdoor noise levels.

- To assess the effect of external and internal environmental factors on the working environment and on workers’ wellbeing.

For more information about the individual sensor packages installed click here

Contact

For more information on any of the above the sensor packages, please contact:

Dr John Orr - jjo33@cam.ac.uk

Dr Cedric Kechavarzi - ck209@cam.ac.uk

Dr Nicky de Battista - n.debattista@eng.cam.ac.uk

Outputs

As the project progresses, links to data and publications will be added to this page. There are various data collection and logging methods across the above six packages. All of the sensor data will be merged with a digital twin of the building, and the digital twin of West Cambridge being developed by CSIC. During design and construction a Revit BIM model has been used, Figure 2.

Figure 2: BIM model screen shot