Using the resources available at the UKCRIC NRFIS, the University of Cambridge Concrete Infrastructure Research Group has been investigating how to optimise cement use in reinforced concrete structures by varying the concrete mix design within elements. Creating spatially variable mechanical properties reduces traditionally conservative coverage of non-controlling material regions and the associated inefficient use of cement.

PhD student Mar Giménez Fernández has focussed on understanding the effect of material grading on the flexural behaviour of reinforced concrete one-way spanning slabs. This will lead to the design of structural concrete elements that can concurrently meet performance and cement reduction objectives. Her experimental work has made use of equipment from multiple NRFIS laboratories including the Concrete Manufacturing Laboratory, the Structures Laboratory and the Smart Infrastructure and Construction Laboratory. The use of these facilities has enabled careful control of the manufacture of the tailored reinforced concrete slab specimens, comprehensive assessment of the concrete properties and detailed tracking of the bending behaviour through serviceability and ultimate limit states.

Manufacture of test specimens

This project made first use of the Concrete Manufacturing Laboratory’s new Intensive Mixer Type R09T, which allows variable rotation speed control of the mixing tools and mixing pan for the mixing process. This mixer enabled sequential batches of different concrete mix designs to be made in short time intervals to successfully achieve good interlayer bonding. The reinforcement cages, prepared using the steel reinforcement cutting and bending station in the Structures Laboratory, were fitted with strain gauges and fibre optic cables prior to concrete casting in order to measure internal local and distributed stains in the reinforcement and the concrete during testing.

Testing systems

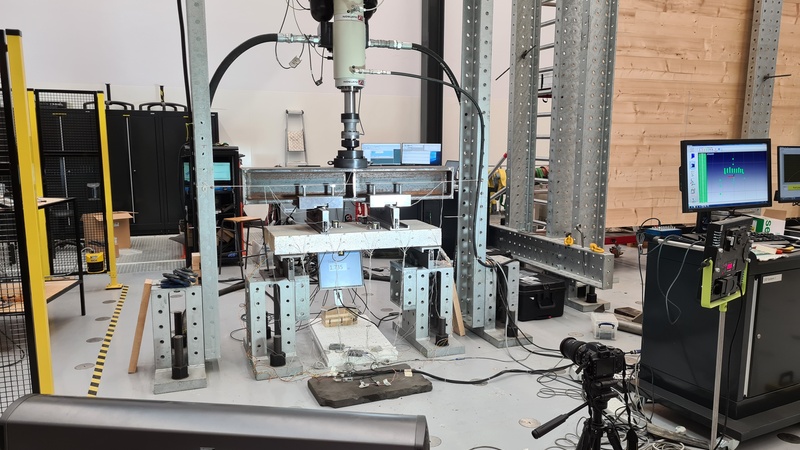

These experiments also made first use of the Structures Laboratory’s new Servo-Hydraulic Ring Main feeding a 160kN Actuator, which was suspended from a bespoke loading frame built using steel Meccano sections on the High Capacity Strong Floor. With this new system, different loading regimes could be carefully implemented to fully capture the details of the deflection and cracking stages in the concrete. Material Characterisation Tests were carried out on standard concrete cube, cylinder and prismatic specimens in the Servo-Hydraulic Concrete Testing System for properties including compressive strength, modulus of rupture, tensile splitting strength and elastic modulus for all of the concrete batches used in the slab specimens.

Sensing systems

Detailed assessment of the flexural behaviour of the tailored reinforced concrete slab specimens was possible due to the use of multiple novel measurement systems. Damage progress assessment was done using the Acoustic Emission (AE) Acquisition and Analysis System. Post-processing of the data acquired using the AE system will be used to assess crack initiation and 3D location propagation, and for analysing fracture modes and fracture energy of the tailored concrete response. Data from distributed strain measurement acquired using an Optical Distributed Sensor Interrogator will be used to interrogate bond capacity, the growth of defects, stiffness degradation and tension stiffening effects. Deflection of the specimens was monitored using a LED Large Field Dynamic Measuring Machine System, which allowed real-time tracking of the 3D position of points on the specimen surfaces. Digital Image Correlation (DIC) was used to assess crack widths and growth kinematics.

This experimental programme has taken full advantage of resources available at the NRFIS laboratories and will deliver new insights into reinforced concrete flexural behaviour and the effectiveness of structural optimisation through concrete grading.

Further information about the Tailored Reinforced Concrete Infrastructure Project, including links to research publications, can be found on https://www.cirg.eng.cam.ac.uk/ResearchThemes/tailoredreinforcedconcreteinfrastructure.

This project is funded by the UK Engineering and Physical Science Research Council (EPSRC) (Grant reference EP/N017668/1). Industry collaborators on this work are Costain, Laing O'Rourke LTD and Skidmore, Owings & Merrill LLP. Mar Giménez Fernández is in Cohort 3 of the EPSRC Centre for Doctoral Training in Future Infrastructure and the Built Environment (https://www.cdt-civil.eng.cam.ac.uk/). Her work is supervised by Prof. Janet M. Lees, and forms part of the Tailored Reinforced Concrete Infrastructure project in the Concrete Infrastructure Research Group (https://www.cirg.eng.cam.ac.uk/).